Alloy Steel Chain Slings

Steel chain slings are regulated under the MIOSHA Part 49 Slings.

Only alloy steel chain, grade 80 or 100 is to be used for overhead lifting. Alloy steel chain will stretch when over loaded; other types of steel may break without warning. Steel chains slings used for lifting are manufactured specifically for lifting. Chains purchased from the hardware store are not to be used for lifting.

Requirements

- An alloy steel chain sling must have a permanently affixed, durable identification, stating the size, grade, rated capacity and reach.

- Chain slings must be inspected daily, before using, for signs of wear and stress.

- Chain slings must be thoroughly inspected, link by link, and the inspection documented at least every 12 months.

- A makeshift link or fastener formed from bolts or rods shall not be used.

- The sling must be proof-tested by the manufacturer when new, repaired or reconditioned. Proof testing is a non-destructive tension test to verify construction and workmanship.

- The manufacturer must be consulted if chains are to be used at temperatures below minus 20ºF.

Daily inspection

Remove slings from service if:

- The identification tag is missing or unreadable

- Cracks in the chain or any components

- Excessive nicks gouges or wear. (Refer to section on measuring wear.)

- Stretched, bent, twisted, or distorted chain links or components.

- Excessive corrosion

- Evidence of heat damage

- Any other condition which may alter the integrity of the chain.

- Binding which means that wear has caused the links to not move freely.

Safe Lifting

- Refer to the manufacturer’s lifting tables for the load reductions when lifting with a multi-leg sling.

- Avoid kinks, loops or twists in the legs.

- Lift slowly to avoid shock loading and stressing the sling.

- Do not pull a sling out from under the load with the load resting on the sling. Block the load up to remove the sling.

- Do not shorten the sling by any means such as knots or bolts.

- Keep metallic slings lubricated and clean to avoid corrosion.

- Slings should not be loaded over the rated load.

- Make sure the sling is assembled properly before lifting.

- Make sure the periodic inspections have been done before lifting.

- The manufacturer should perform all repairs and the manufacturer must proof test all repairs.

- Consult the manufacturer if slings are used at an angle of less than 30º

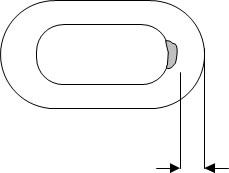

Checking for Wear

If the chain size is less than the maximum allowable wear the chain must be removed from service.

| Chain size (inches) | Maximum allowable wear (X) |

|---|---|

| ¼ | 13/64 |

| 3/8 | 19/64 |

| ½ | 25/64 |

| 5/8 | 31/64 |

| ¾ | 19/32 |

| 7/8 | 45/64 |

| 1 | 13/16 |

| 1 1/8 | 29/32 |

| 1 ¼ | 1 |

| 1 3/8 | 1 3/32 |

| 1 ½ | 1 3/16 |

| 1/3/4 | 1 13/32 |

Chain wear can be measured using a “No-Go” gauge available from the sling manufacturer.

Stretching

To determine if a chain has been stretched measure the length of 10 to 20 links when new and record the length. Compare the length after use to determine if the sling has been stretched. Check the manufacturers specification for the maximum allowable stretch.

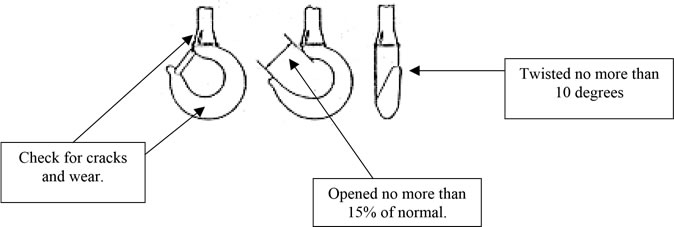

Measuring Deformed Hooks

Remove a hook from service if the hook is cracked or has been opened more than 15% of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.